The unique color of smoked wood: precious parquet from ancient techniques

Change the color of the wood, without using paints or coloring substances, but taking advantage of the presence of tannins naturally contained in its fibers. It is not a dream for the future but what actually happens when we talk about “smoked” wood

Nowadays it is considered a modern and refined finish: the “smoking” of woods, like many other discoveries, was born by chance in England in the past centuries. Random observation of how quickly wood darkened in contact with ammonium vapors produced by horses, became a businness idea, so, between the late nineteenth and early twentieth century, ammonium vapor smoking became increasingly popular among wood craftsmen. This refined technique spread quickly from England across the continents and survived over the centuries.

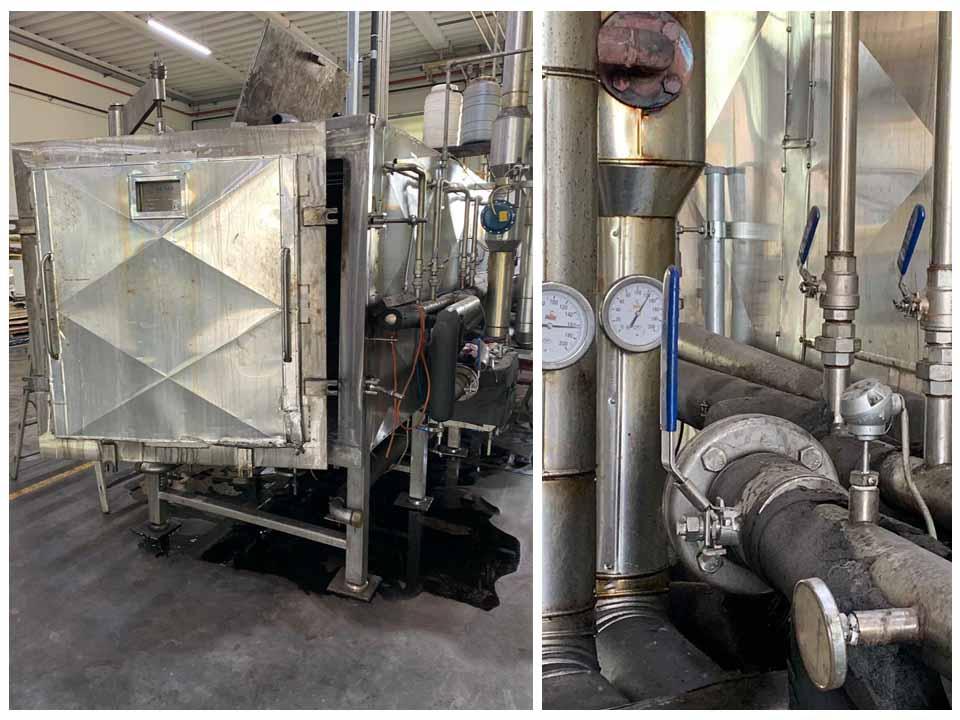

The basic principle of this technique remains the same: obviously, the methods and the environments in charge of this wood treatment have changed. Today smoking with ammonium salts is a controller process that is carried on - in Italy - in a few, highly controlled, rigorous systems selection and safety procedures. The wood is placed in an autoclave and it remains inside for 2-3 weeks, in contact with the ammonium salts and brought to a temperature of 60 ° -70 °. The ammonium vapors react with the tannins of the wood and trigger a reaction that give the wood a special darker color, all through its depth. A true mutation occurs in the wood and the veins become more intense, increasing the charm of the material.

The “Smoking” process changes the wood in its depth, not just on the surface. In the case of Oak, for example, smoking transforms its characteristic straw-yellow color into a warm hazel color, to reach dark brown with deep black veins. It all depends from the concentration of tannins present in the wood and also from the time that the wood remains in the autoclave. A wooden floor made with “smoked” oak parquet is undoubtedly a solution that guarantees stability of appearance and a color that is absolutely resistant to aging and very little photosensitive. In fact, the coloring is not obtained by applying substances on the surface of the wood and so subject to deterioration or wear: it is part of the new structure of the wood itself. Also the mechanical performances change and the wood – after a correct treatment - becomes more flexible and increases its ability to withstand the small signs of wear, as well as its resistance to fungus and moulds.

The result is a perfect wood to create a precious parquet, with natural colors, completely unique and unrepeatable, which reinforce the beauty of the veins and present an extraordinarily textured product, full of charm.

When people come to know that the “smoking” process takes place by contact between woody substance and ammonium vapors, they are suddenly led to think if the floor can be considered healthy – once it will be fitted inside the house - and free of risks for the health. As it happens for all other products - from food to clothes, from make-up products to wine - we can serenely say that all depends on the seriousness of the Company who makes the product, on the quality of the production processes and on the strict compliance with the safety protocols that every sector requires. If processed with due care, the “smoked” wood is toxic-free and does not contain harmful substances. In addition to the correct process and the purity of the products used, it is essential that the ventilation period is respected, once the wood has been removed from the smoking chamber.

With the correct “aeration” period the ammonium vapors that have not yet extinguished their reacting power, will evaporate, leaving the wood completely free of any trace of potentially harmful substances.

Even in the case of smoked wood the reliability of the product is closely linked to the seriousness of the manufacturing Company: for this reason we, at Lignum Venetia s.r.l., choose only the realization of the treatment in Italian plants, managed with highly technological and computerized processes.

Because we care about beauty, but we care even more strictly about the harmony of living and this can only come from a well-being protected in all its aspects.